Mixware Hyper-S 3D Printer

Two-minute review

The Hyper-S FDM printer from Mixware is a new kid on the block, launching, like many other 3D printers, as part of a Kickstarter project. In any other industry, this might feel a little suspect, but creative hardware such as 3D printers, laser cutters and other tools developed to expand the 'makers' space have really found a niche in crowdfunding, which often provides some of the best products on the market.

The Hyper-S thankfully feels right at home in regards to those expectations. Designed to be an all-in-one desktop printer for hobbyists to use at home (rather than a factory or workshop-grade machine), the experience of using the printer can best be described as 'painless'.

The entire setup is near idiot-proof, with minimal assembly required and easy-to-follow instructions to get you started. It's very apparent that the provided instructions haven't had the best translation into English, but they did the job and didn't make the setup too confusing.

The box even comes with some example prints to showcase achievable results across different materials. While we wouldn't consider them appropriate to be considered 'tests', it was great to get a feel of each filament type before printing with them, and it made choosing the right material to use a breeze.

The Hyper-S FDM printer's frame design is very similar to other popular 3D FDM printers on the market such as the Creality Ender 3 and the AnyCubic Vyper. This is an area where innovation isn't really required given we're still in the early days of 3D printing development, but if you wanted something uniquely styled this printer won't impress you.

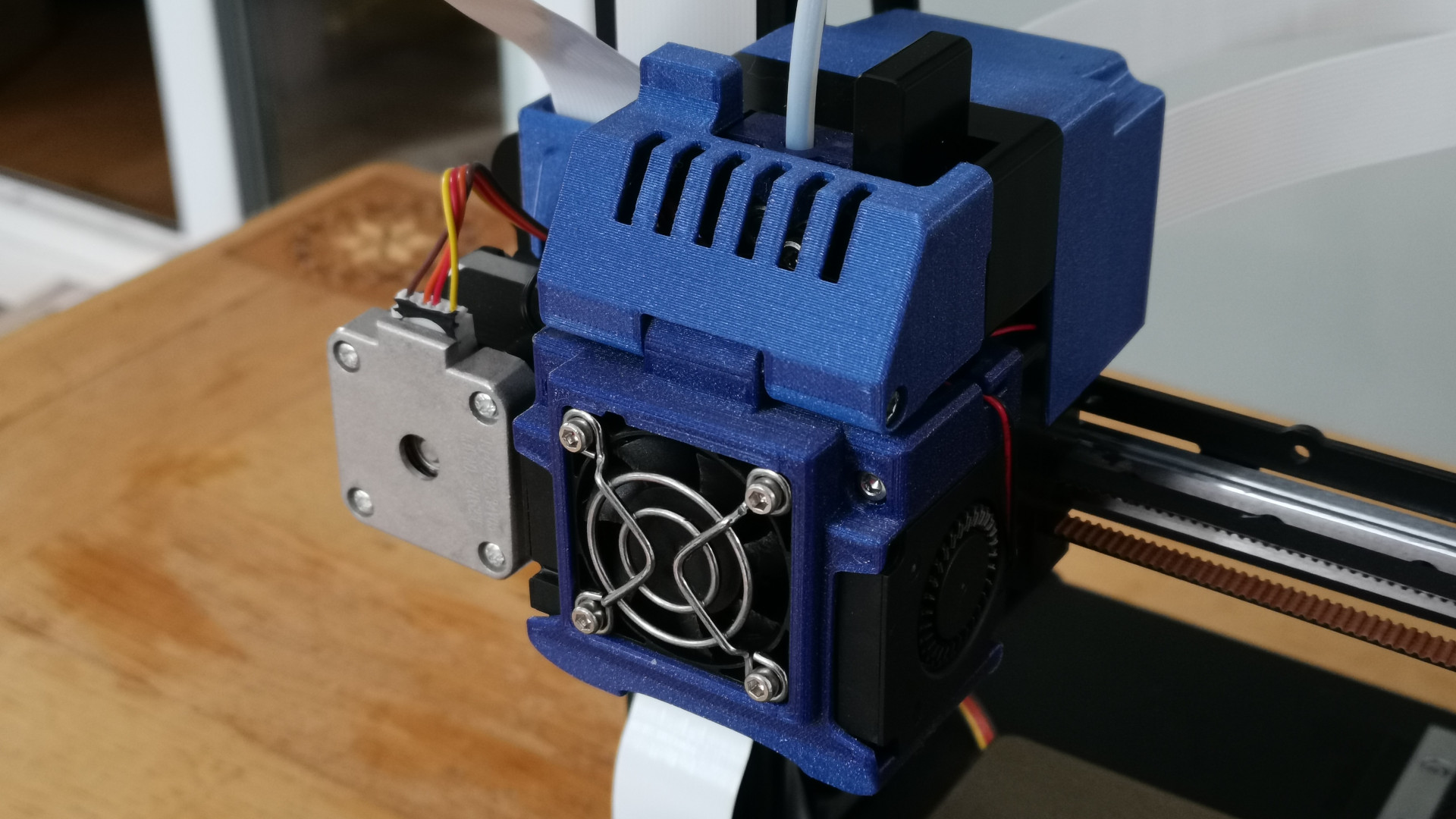

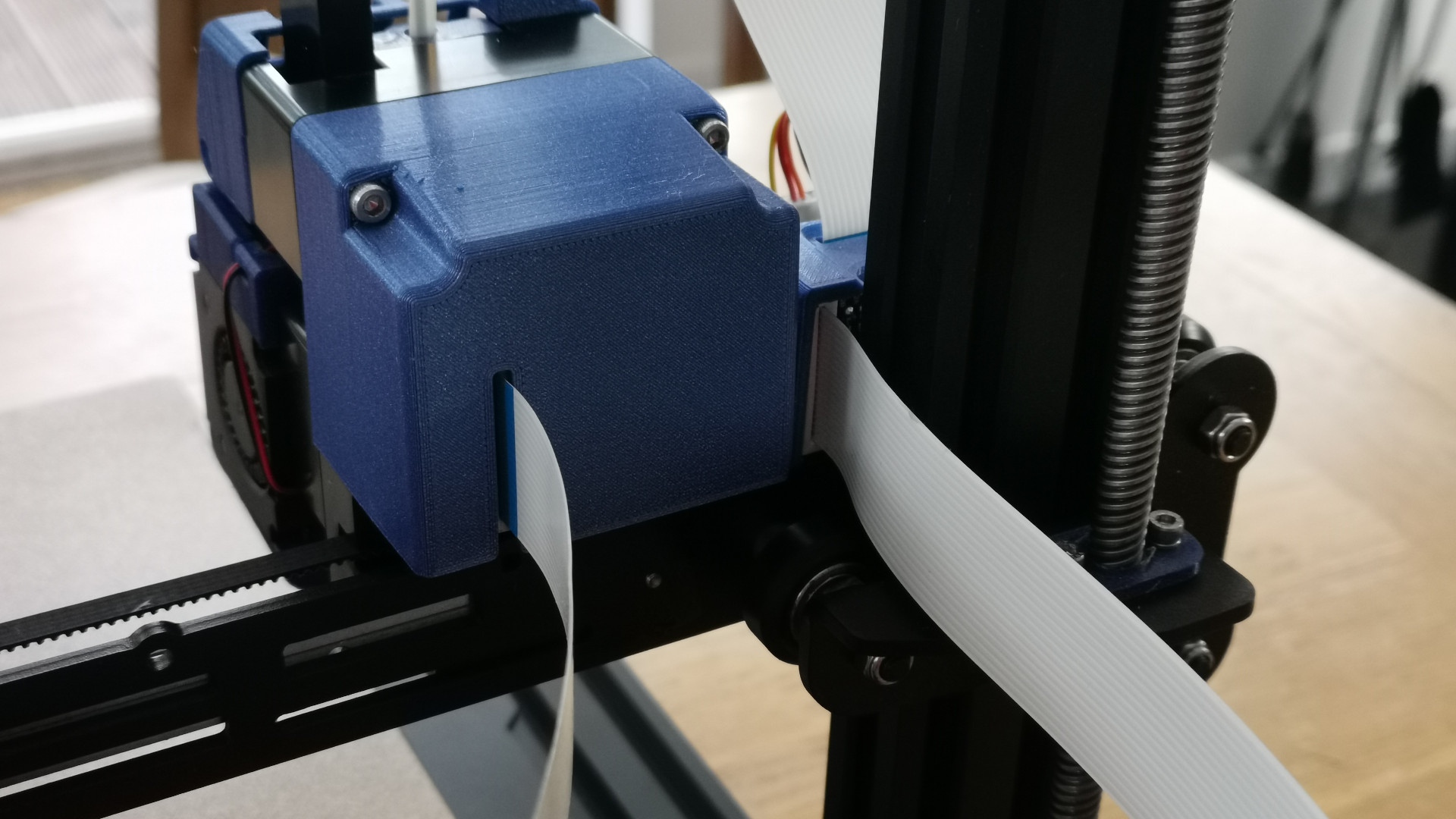

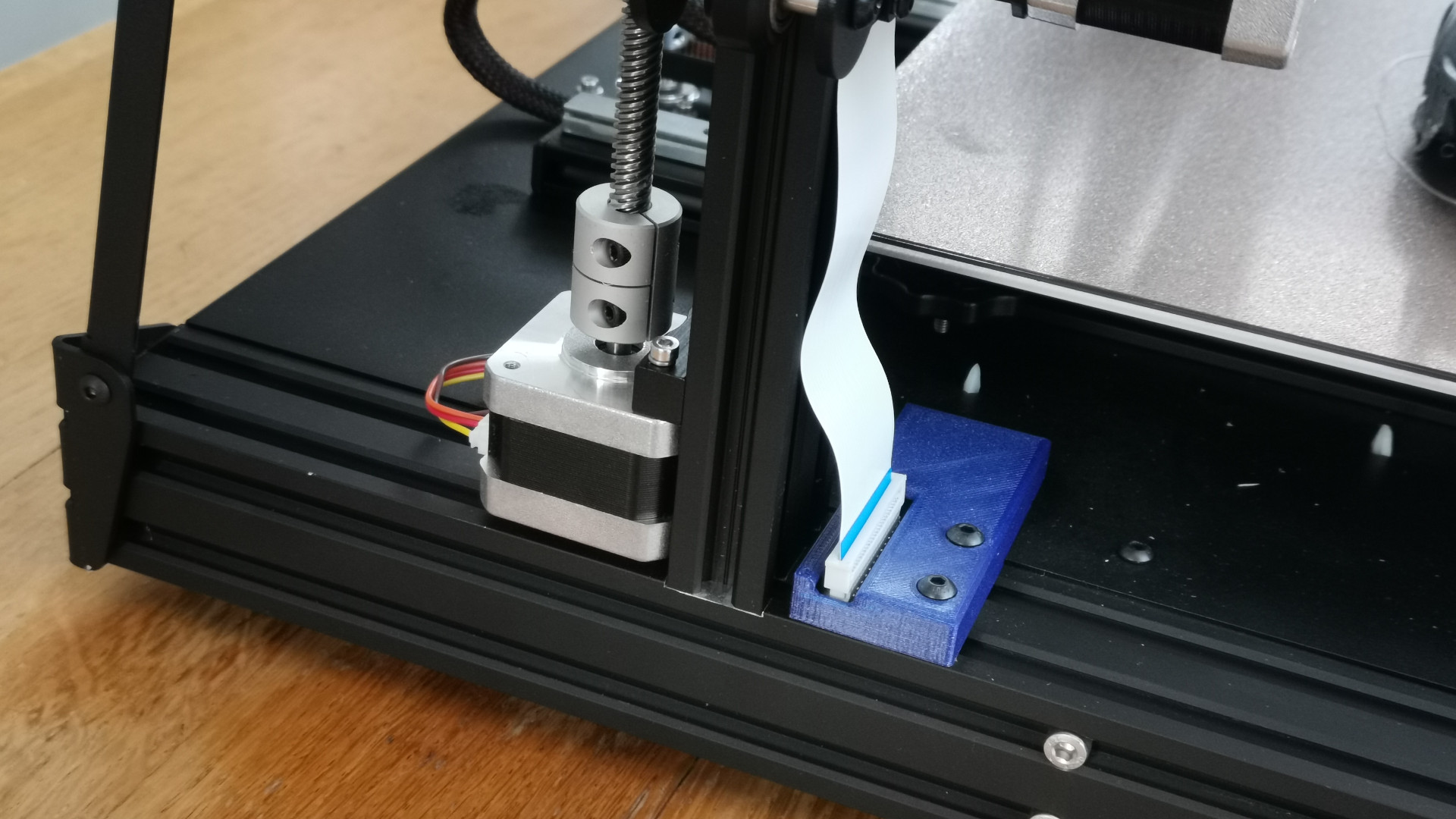

That said, a close look at the components reveals that the printer itself has actually been constructed using 3D printed parts, which is a real showcase of the capabilities of these modern machines.

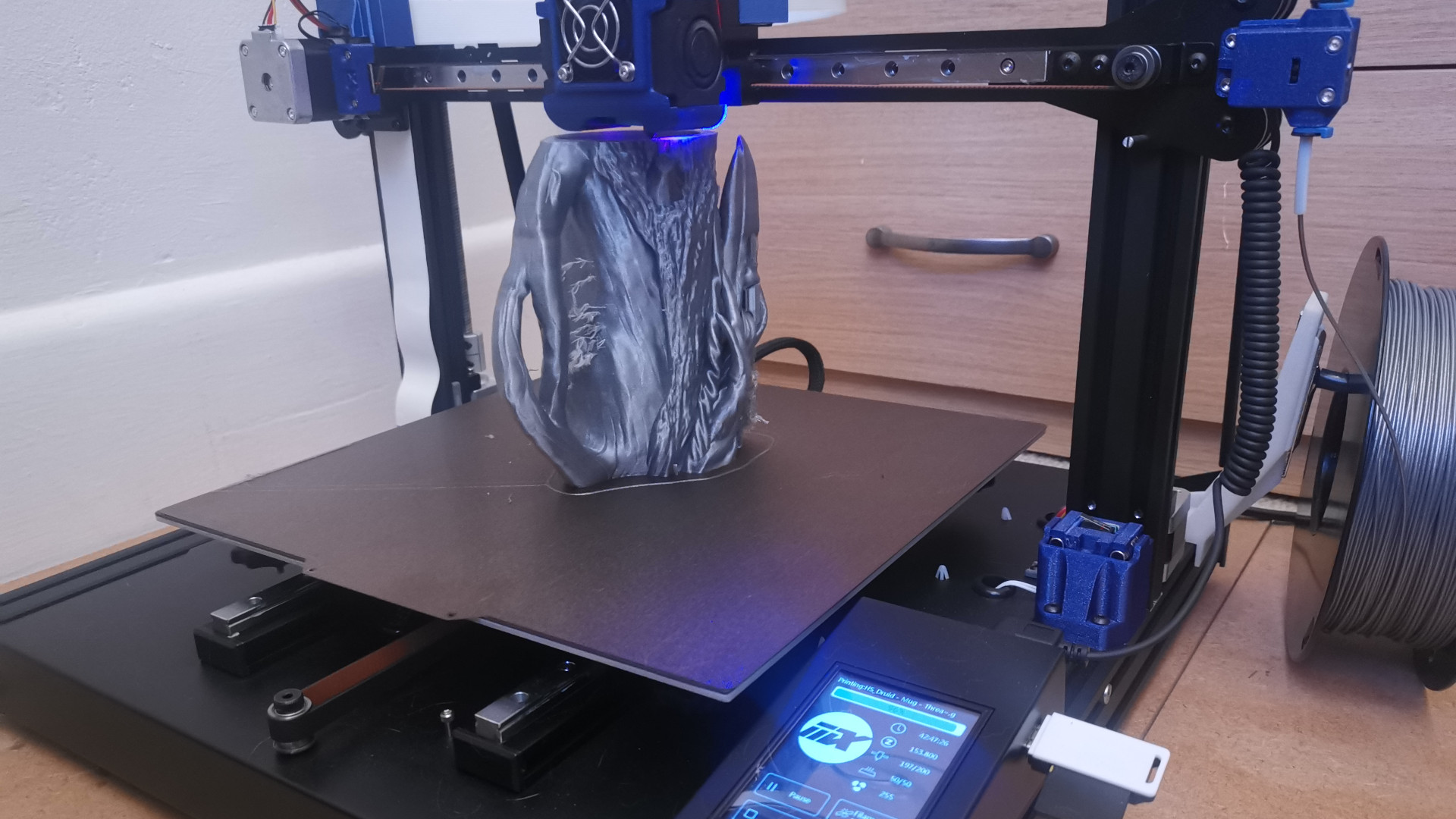

There are a few quality-of-life features for the Hyper-S, such as a magnetic hotbed that certainly make it feel like a great home printer - but outside of any special functions, it's just effortless to use and very beginner-friendly. The touchscreen display is to-the-point and very easy to navigate, and the prints it produces are of a very high quality. Mix that in with all of the usable materials at your disposal and the Hyper-S becomes a pretty easy sell to anyone looking for a great all-rounder.

Price and availability

Here are the specifications for the Mixware Hyper-S 3D Printer

Printing Technology: FDM

Supported filaments: PLA, TPU, ABS, PETG, PA, PA-CF, PA-GF, Hi-temp Nylon, Nylon glass fiber, Nylon carbon fiber

Build Volume: 300mm(L)×300(W)×400mm(H)

Print resolution: ±0.15mm

Positioning accuracy: X/Y 0.01mm

Extruder number: Single

Print Speed:<20 - 150mm/s

Operational Nozzle Temperature: max ≤255°C / max ≤350°C

Operational Hot Bed Temperature: max ≤105°C

Connection mode: USB

Machine size: 437mm×404mm×625mm

Weight: Machine weight: ~14kg

The Mixware Hyper-S is currently available through Kickstarter, though you'll need to act fast if you want to snap up one of the early deals. You can currently grab it for $499 / £370, which is apparently a 55% discount off the standard retail price

That would mean that post-crowdfunding, the RRP would sit at around $1,100 (around £820 / AU$1,500) which is alarmingly high for a hobbyist printer. By contrast, the AnyCubic Vyper has a retail price of $359 (around £255 / AU$460) and the Original Prusa MINI retails for $399 (around £300 / AU$550).

Even with its high-temperature printing capabilities, that's a hard sell. As 3D printers are becoming more commonplace, they're rapidly becoming more affordable so seeing a new launch at this price targeted towards non-industry customers is a little perplexing.

That high price actually makes the Mixware Hyper-S a little difficult to justify given how many other amazing products there are on the market. It's certainly a good product and it has a few qualities that make it incredibly user-friendly, but it's not special enough to warrant that price tag.

Design

The Hyper-S comes flat-packed like many FDM printers, though assembly is an easy process. With two people it took less than 15 minutes to be ready to start printing, though you could probably put it together with just one person - only the part where the frame has to be slotted into place could cause issues if you're going it alone, and everything else is just a matter of tightening a few things into place.

The plastic components of the machine are 3D-printed. While the slightly shimmery look is consistent with some of the filaments provided by Mixware, we haven't verified if the company has printed the parts themselves. Regardless, they're of excellent quality and do a great job showcasing 3D printing's achievable possibilities.

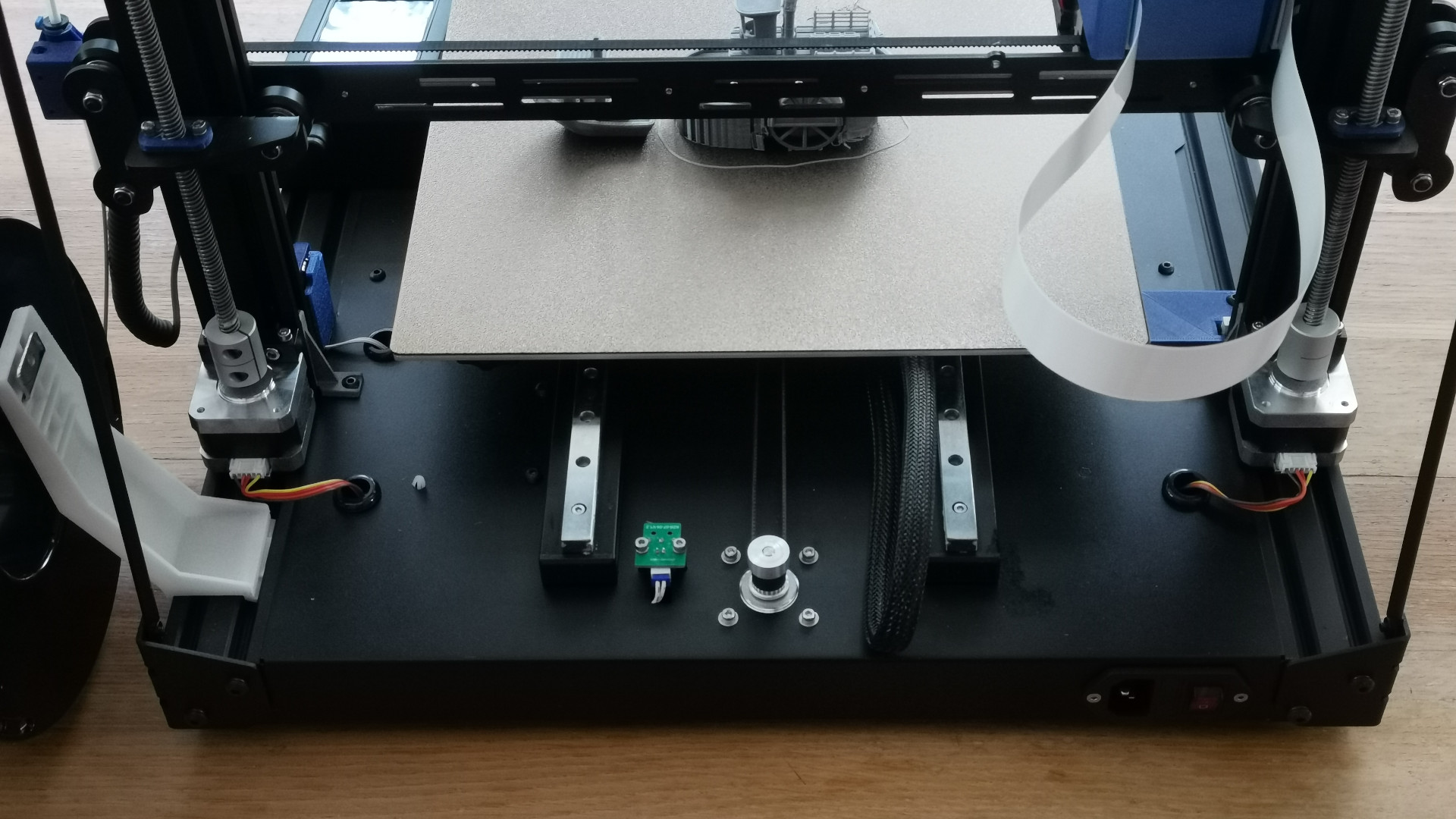

All of the components are well made with no stray glue or messy wiring. The build is semi-exposed so you can see the belt on the underside that movies the built plate, but this isn't uncommon in FMD printers and actually helps educate you on the hardware should it ever need fixing.

The frame is constructed from solid metal, and nothing wobbles or feels precarious when moved, so while it’s not the most lavishly designed printer we’ve ever seen, it’s certainly well built and robust.

The power controls and the power port are located at the rear of the device which can be a little frustrating, both for if you want it to sit flush against a shelf and also to switch the printer on and off after use. Moving the power button to the side would have been an improvement.

The touchscreen display used to control the printer itself is located on the front right, and the USB port to plug in a flash drive is built into it. While the instruction manual has some obvious translation issues, none of that is present on the control panel.

In fact, this is one of the best touchscreen control panels we’ve seen recently on an FDM printer. There are no bells and whistles, but the commands are clearly labeled and it covers the entire range of controls needed to start a print, level the machine and troubleshoot for any issues.

The printer is fairly sized at 300 x 300 x 400mm which allows plenty of space for large prints such as vases or decorative figurines, so if you needed something larger than the current popular options on the market like the Original Prusa i3 MK3S+, then the Hyper-S is ideal.

Features

Like a handful of other printers on the market, such as the AnyCubic Vyper, the Mixware Hyper-S comes with an automatic leveling feature, which is easy to find on the interface, clearly labeled on the home screen alongside options to prepare and preheat your filament of choice.

Many printers are still manually calibrated using a sheet of paper and small, controlled adjustments, so eliminating this requirement is great not just for new hobbyists who might be unfamiliar with the process, but also experienced individuals who might just be sick of doing it.

The leveling process took around two minutes and had zero issues. We only had to level the machine once during its initial setup, though you’ll want to re-collaborate if you move your printers around often. If you plan on keeping it in one location though, it’s unlikely you’d need to level the machine again.

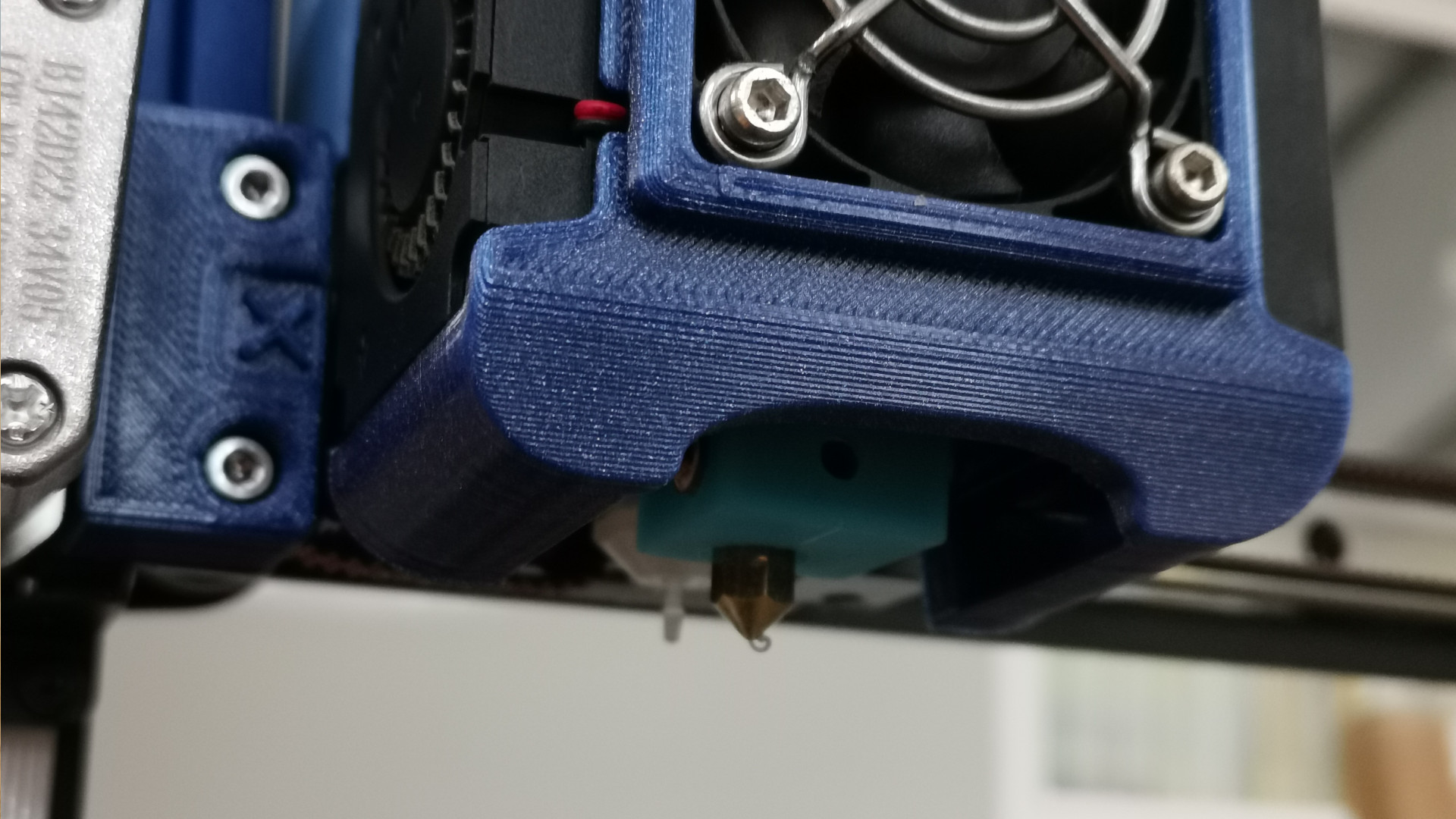

The Hyper-S is advertised as having non-blocking nozzles, though no specific information is in the booklet on what makes this work. Regardless, we did leave the filament hanging for a few hours to cool and then resumed a test print to try this out and the claim does appear to be accurate.

Additionally, there’s a feature on the Hyper-S that quite frankly should be on every printer, regardless of being FDM or resin-based: the build plate is flexible and removable. This is such a simple inclusion but it makes removing prints from the print bed an absolute dream, with no need to involve scrapers or scalpels. It even overhangs slightly to give you something to grab when peeling off the solid plate, attached by magnets for easy re-attachment.

Its ability to print various materials with a max temperature of 350°C / 662°F is also a bonus, especially if you’re keen on project builds such as motorized toy vehicles. You can print the chassis in carbon fiber, the frame is ABS or PLA and even the tires can be printed out using ultralight TPU which is soft and squishy, while having the ability to retain its shape.

Another familiar feature we’re seeing with modern printers is the ability to resume printing after a power outage. We tested this by flipping off the mains power to the machine for an hour, and the printer, as claimed, had no issues getting back to work after a few seconds. From this pattern, it would seem that everything Mixware promises in the Kickstarter campaign is reliable, doing exactly what it says on the metaphorical tin.

Performance

The Mixware Hyper-S is pretty much silent while printing, but it does have an issue out of the box. A filament detection alarm is built into the machine and we found it to be far too sensitive, shrieking constantly while printing. This can be switched off on the settings to spare your ears, but the initial noise isn't pleasant.

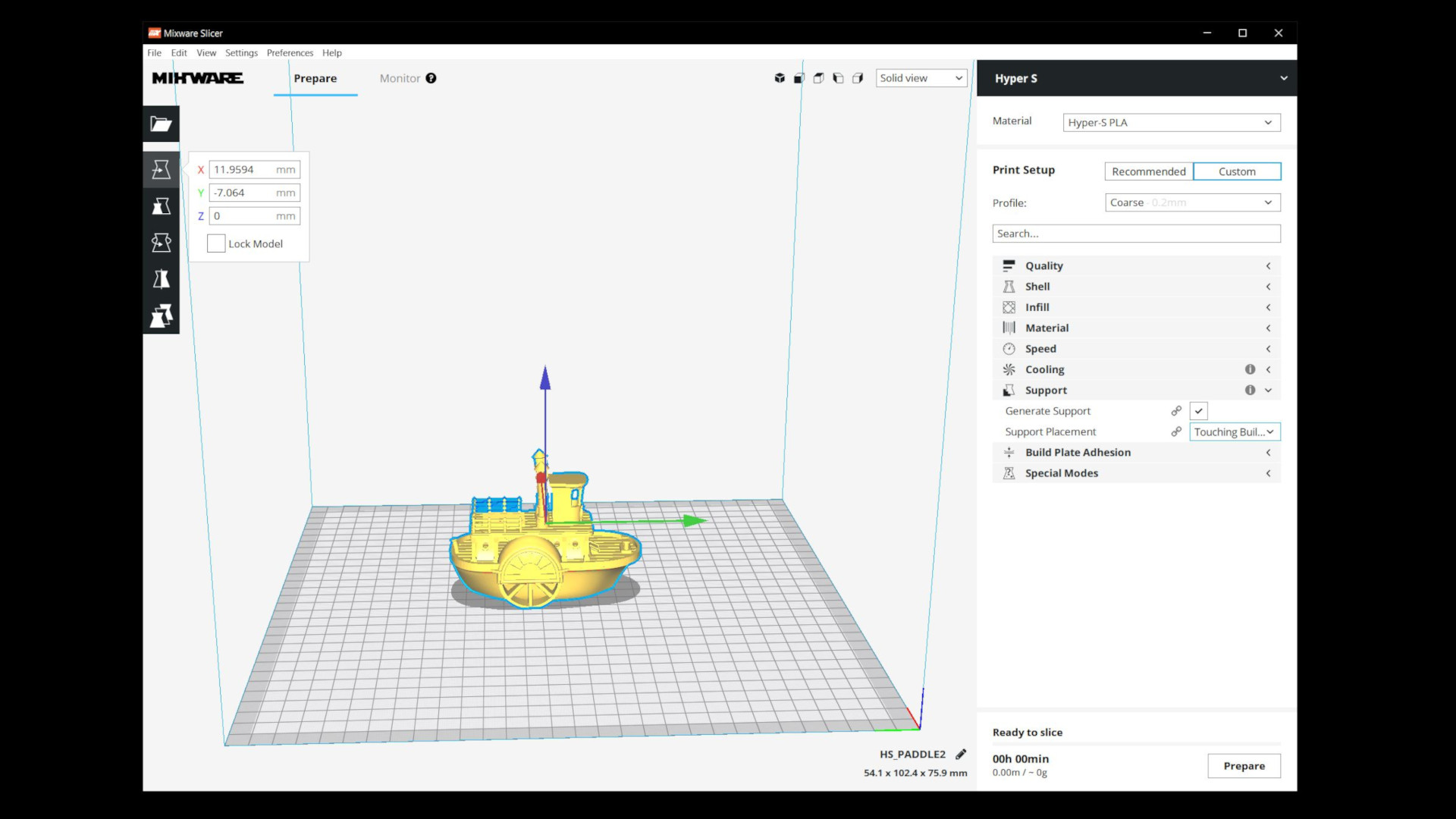

The Hyper-S is compatible with all of the common Slicing software such as Cura, though it comes with its own that you can install from the flash drive. The Mixware Slicer is based on Cura, though with many features and options stripped out which makes prints difficult to optimize.

We used the Mixware slicer for our tests and found that customizing supports and other detailed tweaks that would improve print quality were almost impossible, so if you like to adjust things prior to the printing process, we suggest sticking to Cura or another slicing software if you're more familiar with something else.

That said, there's no need to manually configure the printer into the slicing software like there is with some other machines on the market, and while it lacks features, it's still perfectly usable if you don't tweak your files too much so it's simplicity could be great for anyone who finds Cura too confusing.

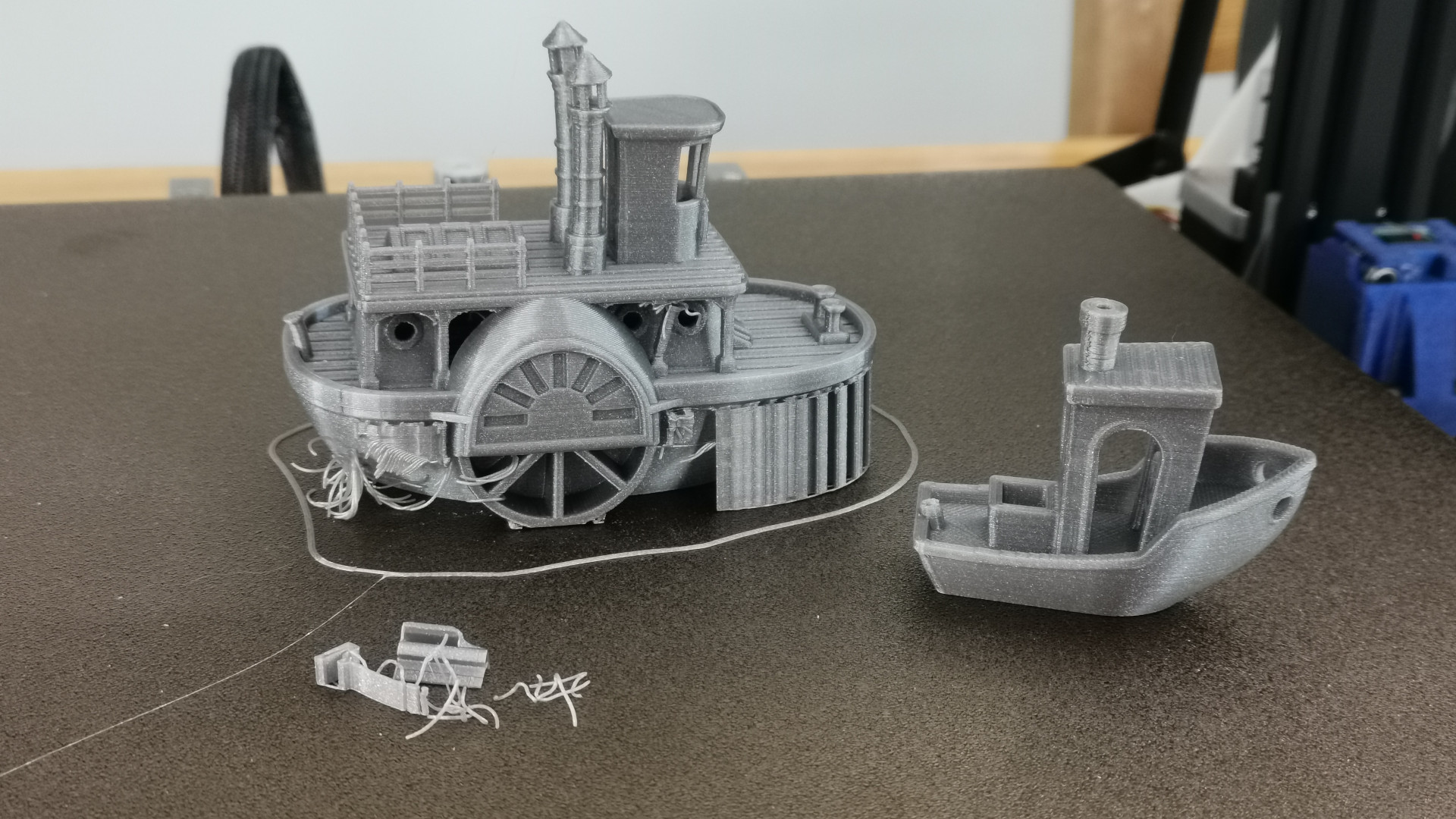

The printing process will begin with the printer drawing a single line of the filament along the side of the build plate - this is intentional so don't be alarmed. Of the prints we tested there were some noticeable support failures, though it's hard to put a finger on if they were caused by human error or the printer itself.

In one of our large benchmarks, a strut printed askew and the supports around the boat figurine looked almost frayed, though the rest of the model did print successfully. This fraying was a common sight we saw across a few of the models we tested, though most were easily removed as any other support would be, even with brushing a finger over them.

You can certainly adjust settings in slicing software to help prevent the drawing but we found it didn't really affect the end quality of the prints themselves. This Druid Mug from Ars Moriendi 3D took around 41 hours and 30 minutes to print with a layer height of 0.1mm, and the detail achieved is incredible.

While print lines are visible in bright environments, the galaxy silver filament from Mixware gave the model some sparkle that helped offset the look of the layers, and the surface is so smooth that it will only require a light sanding before painting.

Its ability to print a range of different materials is a huge bonus, and its large size means you've got plenty of space to create large projects. Even despite its size, it's not an unreasonably sized machine to have in the home, especially if set up in a garage somewhere so this really would make an ideal first machine (or main machine) for an entry-level hobbyist.

Overall, the quality and flexibility of the Hyper-S from Mixware are truly impressive, and the Kickstarter early bird prices are decent enough to jump on board, but if the retail price after the crowdfunded is complete really does jump to $1,100 (around £820 / AU$1,500) then it's difficult to recommend. While the quality is great, it's not all that special enough to warrant such a lofty asking price.

Should I buy the Mixware Hyper-S 3D Printer?

Buy it if...

You want to create large models

The huge build plate on this FDM printer is perfect for large models such as vases, making it ideal for anyone building large props, models and prototypes.

You're new to 3D printing

With the arduous task of manually leveling the machine removed, you can start printing right out of the box, without worrying about too big of a learning curve.

You need to print a range of materials

If you want a mix of different filament types for your projects then this is an ideal product, allowing you to print everything from standard ABS plastic to carbon fiber and even flexible foam.

Don't buy it if...

You want to print miniatures

FDM printers do well on larger models, but if tiny details are your goal then you'll need to look into exploring the world of resin printers instead.

You need something on a budget

Even the Kickstarter prices are far from cheap, and there are more affordable products on the market if you're tight on cash. They might not have all of the features that the Hyper-S does, but if money is an issue then this likely isn't the best choice.

- These are the best 3D printers

0 comments:

Post a Comment