AnyCubic Kobra Go 3D Printer Review

The AnyCubic Kobra range has accelerated AnyCubic's position as a well-respected 3D print manufacturer. The two largest models in the range are visually imposing, with the Kobra Max offering one of the market's largest home 3D print platforms.

The Kobra range may be marketed as entry-level, but the features, construction, and print quality make them stand out in a crowded market.

While the Kobra Go is the entry model in an entry-level range that now consists of five printers, it's far from what an entry-level 3D printer was even a couple of years ago. The build quality is outstanding, and while a little plasticy around the edge, there is little to fault once you consider the price. Then there are the features that include; auto bed leveling, LCD interface, optional filament run-out sensor, and sprung steel magnetic print platform. We'd have expected these features only in mid to high-end printers not too long ago.

As the entry-level model, you'd expect the quality and performance to be lower than the standard Kobra, but in reality, it's very much on par.

Design

3D printer design has evolved. The current trend for 3D printer design is to neatly hide away components, such as power adapters, motors, belts, and gears, rather than leaving them on show.

Build Volume: 250x220x220

Memory: SD Cards

Nozzle size: 0.4mm

Layer Height: 50 - 300 μm

Bed: Sprung Steel

Print Surface: textured

Software: Cura

Materials: PLA, ABS, PETG

Included material: None

Machine dimensions: 490x445x443mm

Machine weight: 7kg

Power: 240v

Generally, this creates a much more aesthetic and robust machine, which is the case with the Kobra Go. While the printer, like most, requires some initial construction, with the vertical frame needing to be bolted into the base and some wires plugged in, the whole process should take no more than half an hour at an absolute maximum. In this review, it took around ten minutes to unpack, bolt together and have the machine in a state where it was ready to print.

The build-it-yourself approach may seem a little daunting for those new to 3D printers. But the process is extremely simple, and most of the construction has already been completed. AnyCubic has also created easy-to-follow videos that run you through the process. One side effect of bolting in the vertical frame and plugging in the wires is that you get to see how the printer goes together and will learn a little about the inner workings as you go.

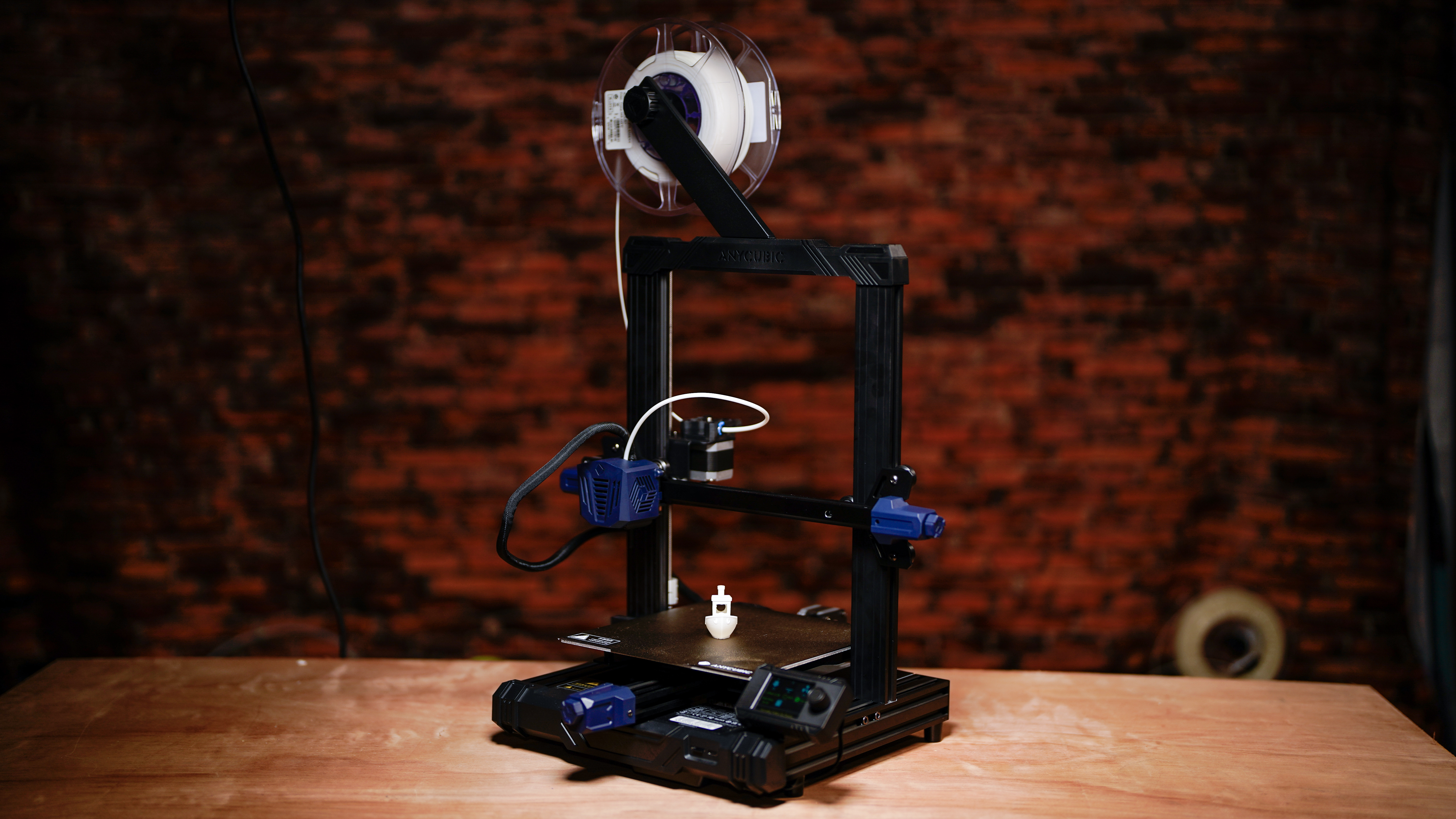

The printer takes on the standard Cartesian design with the main frame utilizing a single thread Z-Axis. On top of the vertical is the filament reel holder, this does increase the height of the 3D printer somewhat, but that does mean that, unlike its larger siblings, it does take up far less desk space. If you want to pop it into a cupboard, then the filament reel holder is quick to remove. At 7kg and measuring 490 x 445 x 443mm, the footprint is slightly larger than the Kobra, but it is still an ideal choice if space and storage are an issue.

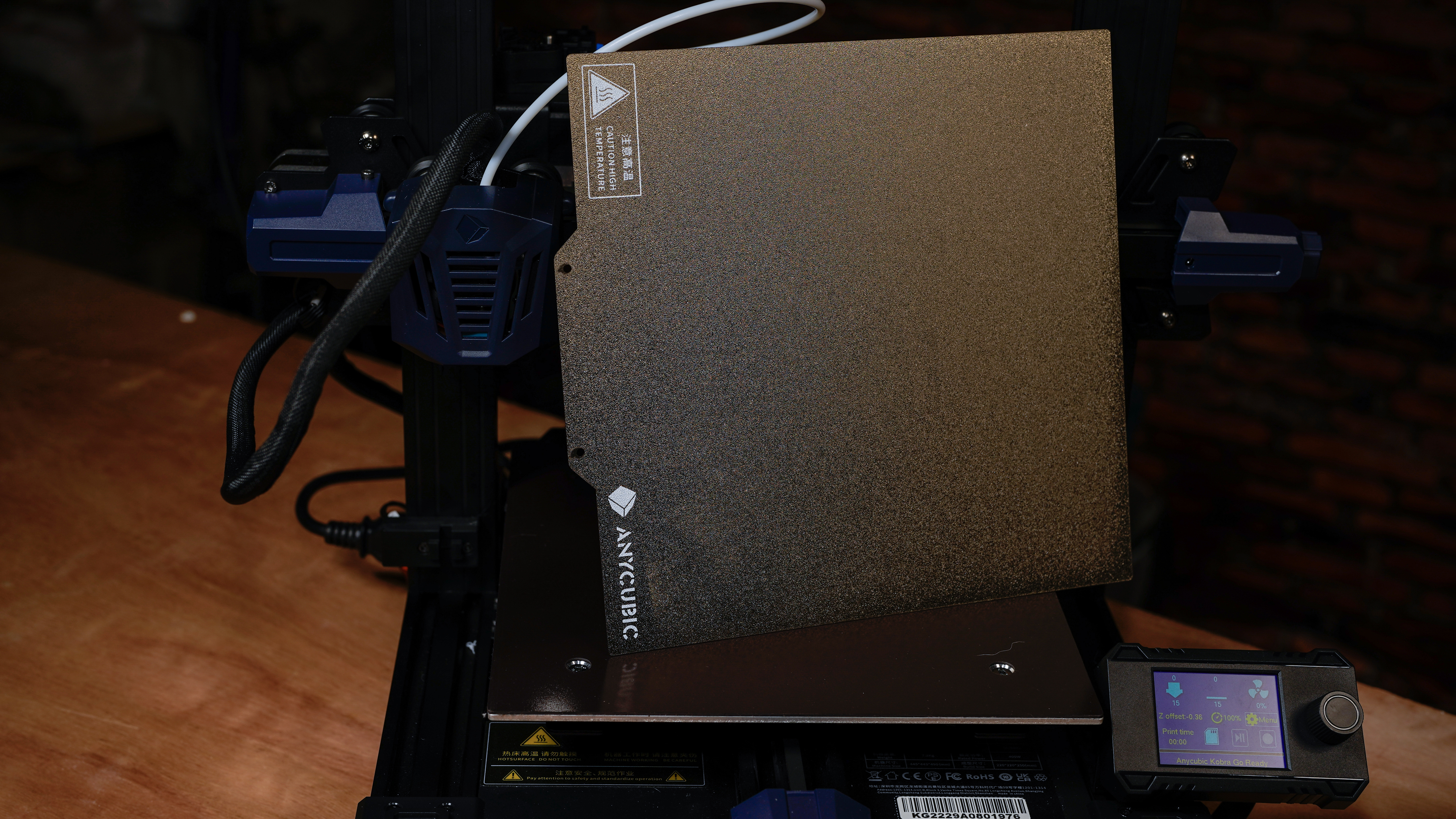

The print platform features a magnetic steel bed, a style I prefer over glass plates. All electronics are stored underneath in a purpose-made and fully enclosed base. This keeps everything tidy and ensures that the printer is incredibly easy to move and store.

When it comes to connections, there is the AC power lead, and then you have a choice of USB direct to your computer, or you can load the models using a d.

Overall, it's a simple yet solid design that, from the outset, gives confidence that this is a well-thought-through and considered 3D printer.

Features

The key feature of the Kobra range is speed, with the larger Plus machine putting in a superb and accurate performance even when printing faster. Likewise, with a printing speed of 100mm/s, this printer isn't slow, although not quite as fast as the standard Kobra model.

The quality of the first layer printed often signals the quality of the rest of the print. The AnyCubic LeviQ is a sensor that checks the bed level at multiple points across the print surface and feeds that data back to the printer to make height adjustments. The inclusion of this sensor is impressive as they are usually only seen on printers two or three times the price.

One of the first signs that this is the entry-level model is the inclusion of an LCD screen rather than touch. This means you must scroll through the options with a dual-function dial. This isn't difficult once you know how it works, but it is a world apart from the simplicity of a decent touch screen.

A feature I always like to see is a sprung steel heated bed, as it makes life so much easier. Generally, prints stick better, and when printing large, the flex it provides enables models to be removed with relative ease. At 22 x 22 x 25 cm, this is the same as the Kobra, and while it is by no means large, it's a decent build area that will exceed the volume required by most.

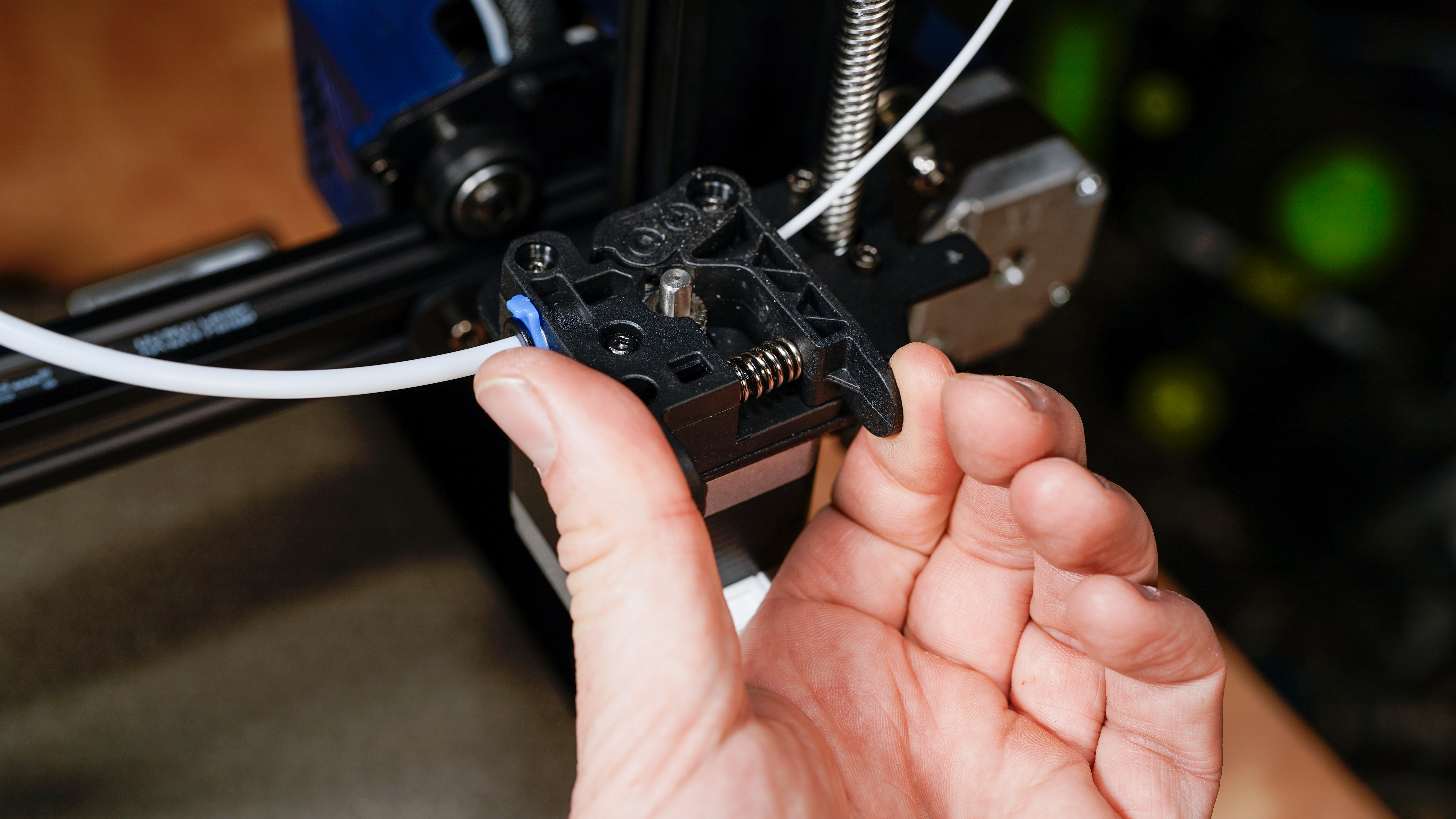

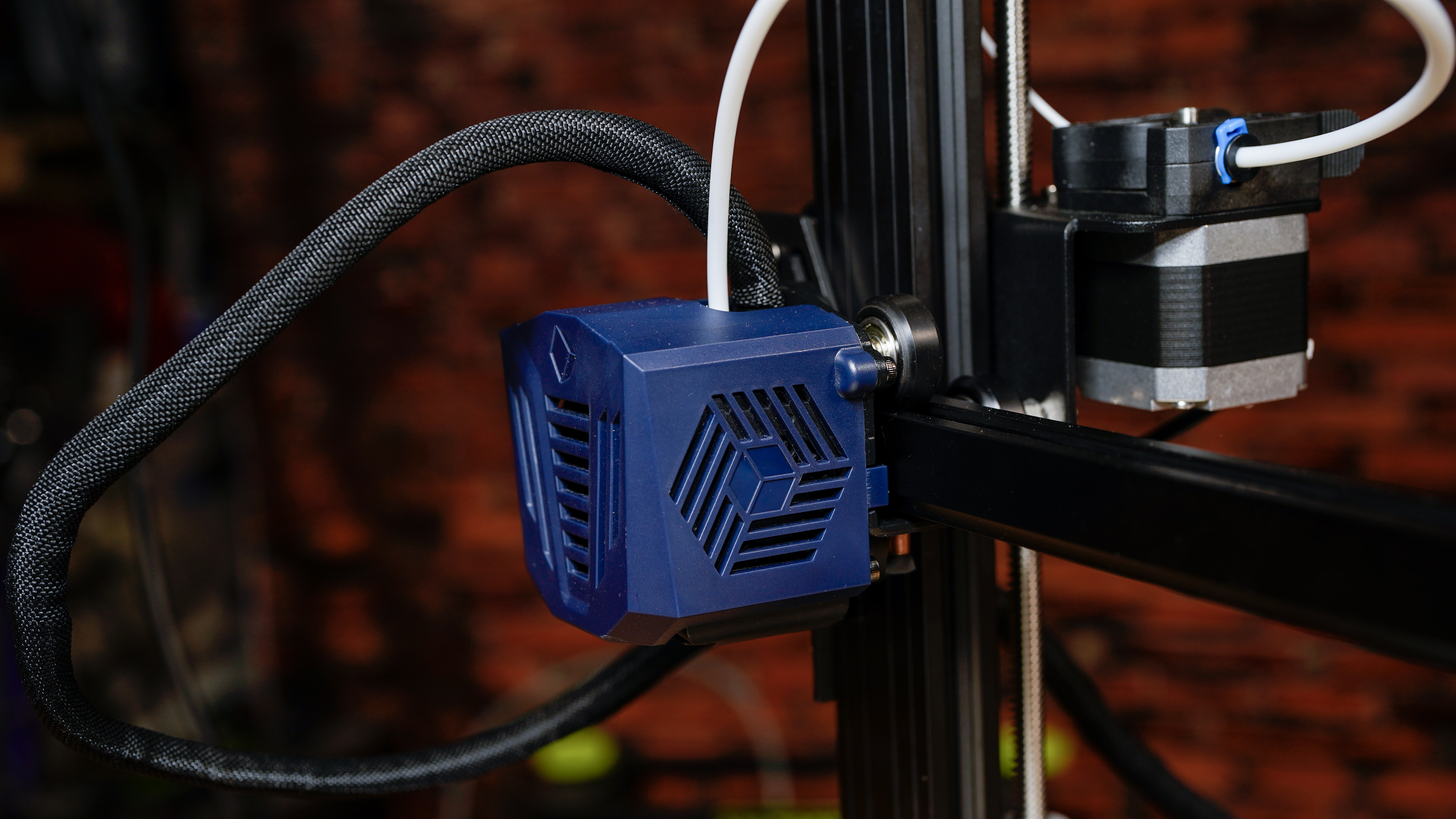

The print head and extruder are of the Bowden design similar to the Kobra Plus; this allows for fast printing and decent material compatibility, although slower than the Standard Kobra and Max models that use direct drive extruders. However, as with the Kobra Plus, it doesn't quite have the range of material compatibility you would get with the direct drive extrusion models.

Performance

The precision, speed, and quality shine through from the moment this entry-level 3D printer starts. The solid construction is reflected in the visual quality of the prints, with the first few layers showing the smooth quality of the motion and extrusion.

Out of the box, the construction is minimal, and while the LeviQ auto bed leveling system does an excellent job, initially, there is a little adjustment of the Z-Axis required. Using the touch screen interface makes finding and adjusting the setting quick, and once done, there was no need to readjust the Z-axis or any other settings for the printer for the test duration.

Several features stood out from the initial prints through to the longer-term test. The first was reliability; this is a printer you don't have to think about technically or mechanically; after that initial adjustment of the Z-axis and a check of belt tensions, the rest of the printing journey has been smooth and trouble-free.

The print head is a solid performer coping with all standard materials easily, and results from PETG and PLA look especially fine. ABS also printed well, but then the temperature during the test in the workshop was a good and consistent 25ºC, so there have been no signs of warping or other issues usually associated with printing these more advanced materials in an open frame printer.

While the rest of the Kobra range stands out due to its speed, the Kobra Go is slightly more sedate regarding print speed. The print times are still good, but pushing the speed to the maximum of 100mm/s does start to show a fall-off in print quality. Model quality is generally excellent at 60mm/s, which AnyCubic highlights as the available print speed.

Overall, the performance for a printer of this size and price bracket is outstanding, the Kobra Go may not have the speed of the standard Kobra, but it does match the larger Kobra Plus. Overall quality counts here, and to that end, there's no doubting the print quality.

Print quality

The initial prints showed excellent print quality utilizing the normal print settings; the speed was good, but what stood out was the layers' accuracy. Increasing the print quality and pace takes a step down, as you'd expect, but you see reduced layer height and visibility decrease.

Taking the printer up to the maximum print speed and lowest quality and the printer puts in a decent performance. The speed is good, and the print quality is more than passable, far better than many high-end draft mode qualities from other printers. However, compared to the standard Kobra at £100 / $100 more, there is a marked difference in print speed and accuracy. While the prints from the Kobra Go look good, they're not a patch on the Kobra standard, which has the edge.

After running through several prints, there is a noticeable print speed difference between the Kobra and Kobra Go, and the major difference in the prints is the accuracy. The Kobra is much tighter on dimensional accuracy compared with the Go.

Visually, however, the prints from both printers are excellent.

After running through the usual 3D Benchy and a few personal models, it was time to run through the Autodesk Kickstarter test model with the following results.

Dimensional accuracy - score of 4

Target 25 = X: 24.90mm / 0.1mm Error | Y: 25.10mm / 0.1mm Error

Target 20 = X: 19.96mm / 0.04mm Error | Y: 20.33mm / 0.33mm Error

Target 15 = X: 15.21mm / 0.21mm Error | Y: 15.28mm / 0.28mm Error

Target 10 = X: 9.99mm / 0.01mm Error | Y: 10.15mm / 0.15mm Error

Target 5 = X: 5.09mm / 0.09mm Error | Y: 5.11mm / 0.11mm Error

X Error Average = 0.09

Y Error Average = 0.19

X&Y Error Average = 0.14

Fine Flow Control - score of 2.5

Fine Negative Features - score of 2

Overhangs - score of 3

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 21.5 out of 30.

Verdict

Once assembled, the build quality is excellent, and while a little plasticy around the edges, it's all solid and built to last. The advances in 3D print technology are apparent. Although this is entry-level, features and print quality are well beyond what you would have expected in the past, with the filament runout, LCD screen, and auto bed leveling.

The general operation of the machine is relatively simple. Load the STL file onto an SD card, then pop it into the machine. A simple dial-and-click interface enables you to maneuver the functions and features and select the model ready for print.

The interface isn't the most straightforward, and considering the rest of the range features a touch screen, the simple color LCD does seem like a step back. However, once you know the process of selecting models for print, it's all straightforward.

One point of note is that the machine is available with the option filament run-out sensor. This is essential, and it's good to see this as part of the initial purchase options, so well worth the small additional cost.

The Kobra Go is an excellent machine and an ideal option for anyone just getting into 3D printing. It does have a few small niggles, such as the LCD manual interface rather than the touch screen, it's slower than some other Kobra models, and there are limited upgrade options. But, at its heart is a solid and high-quality printer for very little money. This is a great option if you want to take your first venture into 3D printing. If you're experienced in 3D printing and need a cheap workhorse as long as you're not too bothered about dimensional accuracy, this entry-level printer is more than capable.

Effectively the Kobra Go raises the 3D printing stakes. AnyCubics entry-level Kobra model might be slightly paired back on features, but when it comes to aesthetic print quality, it's able to compare with £500+ machines, and that's impressive.

- Looking for a new laptop for your business? Check out our best business laptops

0 comments:

Post a Comment